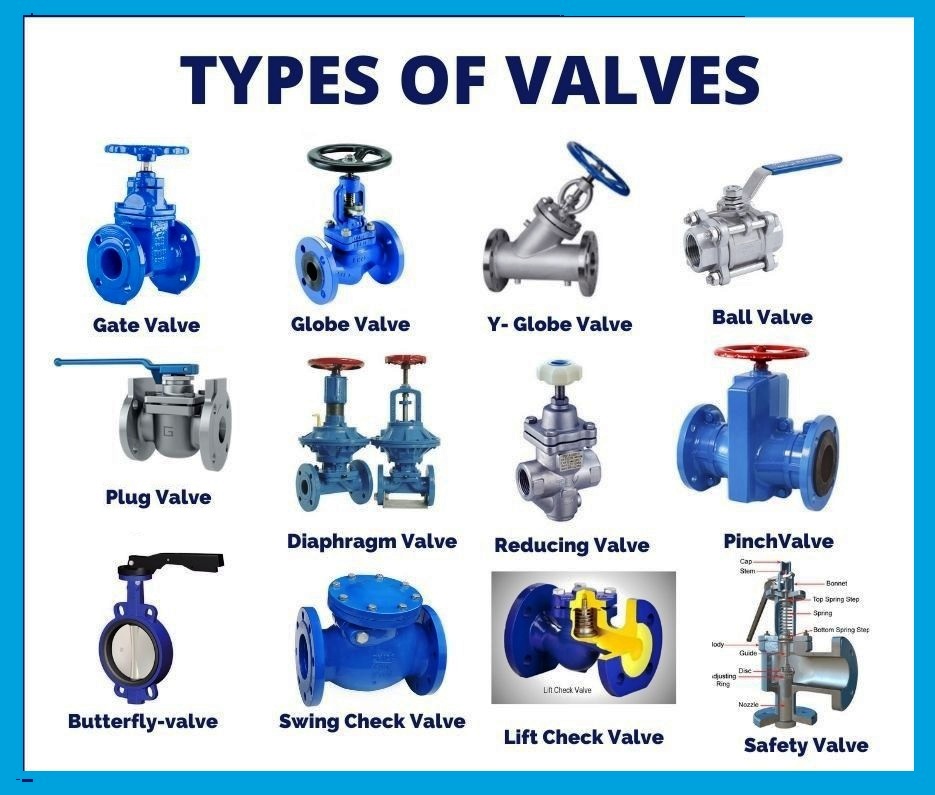

Valves are essential components in various industries, including plumbing, hydraulics, pneumatics, and process control. They serve to control the flow of fluids, gases, or other substances. This comprehensive guide will explore the different types of valves, their functions, applications, and key characteristics types of valves.

Valve Classification

Valves can be classified based on their function, construction, and operating principle. Here are some of the most common types:

1. Gate Valves

- Function: Used to regulate or completely stop the flow of a fluid.

- Construction: Typically have a rising stem and a gate that slides across the flow passage.

- Applications: Widely used in water supply systems, pipelines, and industrial processes.Gate Valve

2. Globe Valves

- Function: Used to regulate or completely stop the flow of a fluid.

- Construction: Have a rising stem and a plug that rotates within a seat to control the flow.

- Applications: Suitable for high-pressure and high-temperature applications, as well as for throttling and isolation purposes.Globe Valve

3. Ball Valves

- Function: Used to regulate or completely stop the flow of a fluid.

- Construction: Have a rotating ball with a hole through it. The ball can be rotated to allow or restrict flow.

- Applications: Widely used in various industries due to their simplicity, reliability, and quick operation.Ball Valve

4. Check Valves

- Function: Allow flow in one direction only and prevent backflow.

- Construction: Have a clapper or ball that prevents reverse flow.

- Applications: Used in pump discharge lines, piping systems, and hydraulic circuits.Check Valve

5. Plug Valves

- Function: Used to regulate or completely stop the flow of a fluid.

- Construction: Have a plug that rotates within a seat to control the flow.

- Applications: Suitable for high-pressure and high-temperature applications, as well as for throttling and isolation purposes.Plug Valve

6. Butterfly Valves

- Function: Used to regulate or completely stop the flow of a fluid.

- Construction: Have a disc that rotates within a valve body to control the flow.

- Applications: Widely used in large-diameter pipelines and industrial processes.Butterfly Valve

7. Diaphragm Valves

- Function: Used to regulate or completely stop the flow of a fluid.

- Construction: Have a flexible diaphragm that flexes to control the flow.

- Applications: Suitable for applications involving corrosive or abrasive fluids.Diaphragm Valve

8. Pinch Valves

- Function: Used to regulate or completely stop the flow of a fluid.

- Construction: Have a flexible pinch that closes off the flow passage.

- Applications: Suitable for applications involving abrasive or slurry fluids.Pinch Valve

Valve Materials

Valves can be made from various materials, including:

- Metals: Carbon steel, stainless steel, bronze, brass, cast iron

- Non-metals: Plastics (PVC, PTFE), rubber, ceramic

Valve Actuators

Valves can be operated manually or using actuators. Common types of actuators include:

- Manual: Handwheels, levers, or gearboxes.

- Electric: Motors or solenoids.

- Pneumatic: Compressed air cylinders.

- Hydraulic: Hydraulic cylinders.

Valve Selection Considerations

When selecting a valve, consider the following factors types of valves:

- Fluid Properties: The type, temperature, pressure, and flow rate of the fluid.

- Valve Size: The required size of the valve based on the pipe diameter and flow rate.

- Valve Material: The compatibility of the valve material with the fluid.

- Operating Conditions: The temperature, pressure, and corrosive environment.

- Maintenance Requirements: The ease of maintenance and repair.

- Cost: The initial cost and ongoing maintenance costs.